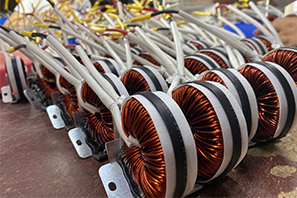

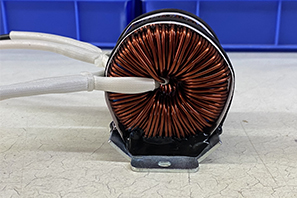

The transformer coil is one of the core components of a transformer, and its main function is to transmit and convert electrical energy through electromagnetic induction. The design and material selection of transformer coils have a crucial impact on the performance, efficiency, and reliability of transformers. The following is a detailed discussion about transformer coils:

Copper electromagnetic wire

High conductivity: Copper has high conductivity and low resistance, which can effectively reduce energy loss.

High mechanical strength: Copper wire has high mechanical strength and durability, making electromagnetic wire suitable for use in high stress environments.

Good weldability: Copper wire is easy to solder and reliable to connect.

Aluminum steel electromagnetic wire

Low cost: Aluminum has a lower price and can significantly reduce the material cost of transformers.

Lightweight: The low density of aluminum reduces the weight of transformers.

Copper clad aluminum electromagnetic wire

Cost effectiveness: Combining the advantages of copper and aluminum, it has lower costs and better conductivity.

Moderate weight: lighter than pure copper wire, but heavier than pure aluminum wire.

Insulated copper wire single layer coil

Simple and easy to manufacture: The structure is simple, and the manufacturing process is relatively easy.

Good heat dissipation: A single-layer structure is conducive to heat dissipation.

Insulated copper wire Multi-layer coil

Compact design: The multi-layer structure can achieve higher power density in limited space.

Good electromagnetic performance: Multilayer structure helps to improve electromagnetic coupling efficiency.

Flat winding of Insulated copper wire

Easy to operate: The winding process is simple and suitable for large-scale production.

Low cost: The manufacturing cost is relatively low.

Cross winding of Insulated copper wire

Good electromagnetic performance: Cross winding can reduce magnetic leakage and improve electromagnetic coupling efficiency.

Compact design: suitable for high power density applications.

Enamelled wire: insulated copper wire for electromagnet, coated with a layer of insulation paint on the surface of the wire, commonly used in small transformers.

Insulation paper: used for insulation between coils, commonly found in large transformers.

The design and material selection of transformer coils need to comprehensively consider electrical performance, mechanical performance, cost, and application scenarios. Through reasonable design and optimization, the efficiency and reliability of transformers can be improved to meet the needs of different applications.

PREV