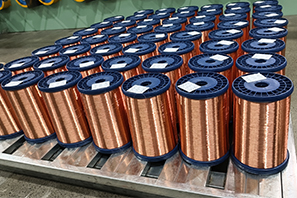

Enameled copper clad aluminum wire has a wide range of applications and can be applied to various large, medium, and small power transformers; Various types of electromagnetic inductance coils; Various high-speed motors such as water pumps, washing machines, fans, garden tools, vacuum cleaners, etc.

Firstly, in terms of electrical resistivity, taking 15A copper-clad aluminum enameled wire as an example, its electrical resistivity is about 1.46 times that of copper enameled wire. For Rongda copper clad aluminium wire, according to the resistance calculation formula, under the same resistance conditions, the cross-sectional area (volume) of the device winding will increase by 46% for a unit length of wire, and the wire diameter will increase by about 21% after substitution. If the window area and skeleton volume (space) of the device's magnetic core have a large margin, that is, after increasing the wire diameter accordingly, the winding can be installed into the original skeleton and magnetic core. Then, the method of increasing the wire diameter according to the wire diameter ratio can be used to replace copper enameled wire with copper enameled wire, without the need to replace the original device's magnetic core and skeleton. Utilizing high-quality enameled copper clad aluminum wire is an excellent way to reduce overall component weight while maintaining reliable electrical conductivity. If the winding cannot be installed into the original skeleton or magnetic core after replacement, the overall structure needs to be redesigned.

Secondly, in terms of density: Taking 15A copper clad aluminum enameled wire as an example, the density of copper clad aluminum enameled wire is 3.63g/cm3, which is about 40.8% of that of copper enameled wire (the density of copper enameled wire is 89 g/cm3). After calculation, under the same resistance conditions, the mass of copper coated aluminum conductor per unit length is 60% of that of pure copper conductor. According to the actual reference, the average weight content of copper resin paint is 3%, and the content of copper coated aluminum resin paint is 7.5%. The weight of the substitute copper clad aluminum enameled wire is 63% of that of the copper enameled wire.

Again, temperature rise situation: Taking 15A copper clad aluminum enameled wire as an example, its specific heat capacity is about 1.62 times that of copper enameled wire. According to the formula for calculating specific heat capacity, when a unit length of wire absorbs the same amount of heat under the same resistance conditions, the ratio of temperature rise between the two is equal to the inverse ratio of specific heat capacity value to weight. Therefore, under the same resistance, current, and power on time conditions, the temperature rise of the substitute device remains basically unchanged, and even slightly decreases. While increasing the cross-sectional area of the conductor also increases the heat dissipation area, further reducing the temperature rise, thereby prolonging the aging process of the insulation material and improving the lifespan of the device.

Finally, mechanical performance: The tensile strength of copper clad aluminum enameled wire is 96~135MPa, which is about 44%~51% of that of copper enameled wire (the tensile strength of copper enameled wire is 215~265MPa), and the elongation of copper clad aluminum enameled wire is slightly smaller than that of copper enameled wire. However, by adjusting the tension of the winding machine and avoiding repeated bending, as well as enhancing surface lubrication and reducing winding resistance, copper clad aluminum enameled wire can meet the mechanical performance requirements of the winding.

Firstly, the price is low. In the current market situation of LME copper at 9700 USD and aluminum at 2400 USD, the price of Rongda enameled copper clad aluminum wire is around 7000 USD, while the price of copper enameled wire is at least 10500 USD. It is 2/3 of the price of pure copper wire.

Secondly, with less weight, as shown in the table above, achieving the same electrical resistivity, the weight of copper clad aluminum enameled wire is reduced to 63% of that of pure copper enameled wire.

Thirdly, without considering the difference in process losses, using enameled copper clad aluminum wire can reduce the unit product cost to 0.667 * 0.63=42%

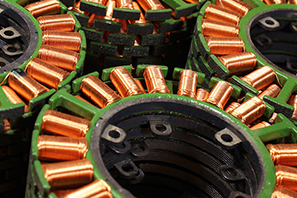

Fourthly, in practical application, customers can develop appropriate enameled copper clad aluminum wire based on product requirements, reducing costs while ensuring normal quality. For example, for the motor stator, copper clad aluminum enameled wires with low copper content can be used appropriately, while for the rotor, better tightness is required in the production and manufacturing process, and better physical properties are required for the wire. It is recommended to use copper clad aluminum enameled wires with high copper content (such as 15A).