Polyurethane aluminum enameled wire is a type of enameled wire that uses aluminum as the conductor material and polyurethane resin as the insulation layer. Aluminum, as a lightweight and relatively low-cost metal, has good conductivity, while polyurethane, as an insulation layer, not only provides excellent electrical insulation performance, but also has a series of additional advantages, making this type of enameled wire very popular in various applications.

| Product Name | Polyester Enamel Aluminum wire | |||

| Type | QAL/155 | UEW/155 | QAL/180 | UEW/180 |

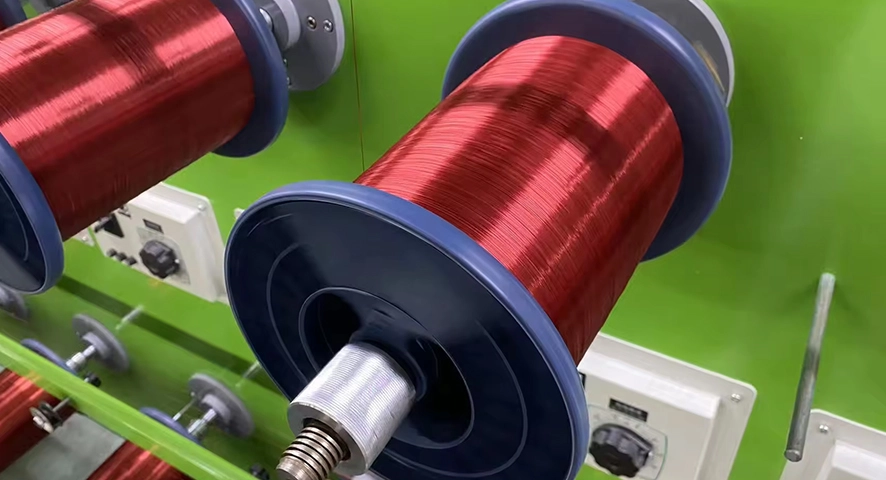

| Coating color | Red | Golden | ||

| Size | 0.13-0.45 MM | |||

| Coating thickness | -1 | -2 | ||

| Spool packing | PT10 | PT15 | PT25 | |

| Thermal class | F 155°C | H 180°C | ||

| Standard | GB 6109 | IEC 60317-0-3 | ||

This product has direct weldability, good high frequency resistance, easy coloring and good moisture resistance. It is widely used in electronic appliances, precision instruments, telecommunications instruments.

1. Excellent electrical insulation performance: Polyurethane provides excellent electrical insulation, which helps to improve the safety and reliability of electrical equipment.

2. Direct solderability: A significant feature of polyurethane aluminum enameled wire is that it can be directly soldered without the need to remove the insulation layer before welding. This feature simplifies the manufacturing and maintenance process of electronic components.

3. Good heat resistance: The polyurethane insulation layer can withstand a certain temperature and is usually suitable for Class F (155 °C) applications, meeting the heat resistance requirements of most electronic devices.

4. Mechanical strength and flexibility: The polyurethane layer also provides good mechanical strength and flexibility, allowing the aluminium winding wire to withstand certain mechanical stresses, such as bending and twisting, without being easily damaged.

5. Chemical stability and moisture resistance: Polyurethane has good resistance to various chemicals and moisture, which helps protect the stability and lifespan of aluminum conductors in harsh environments.