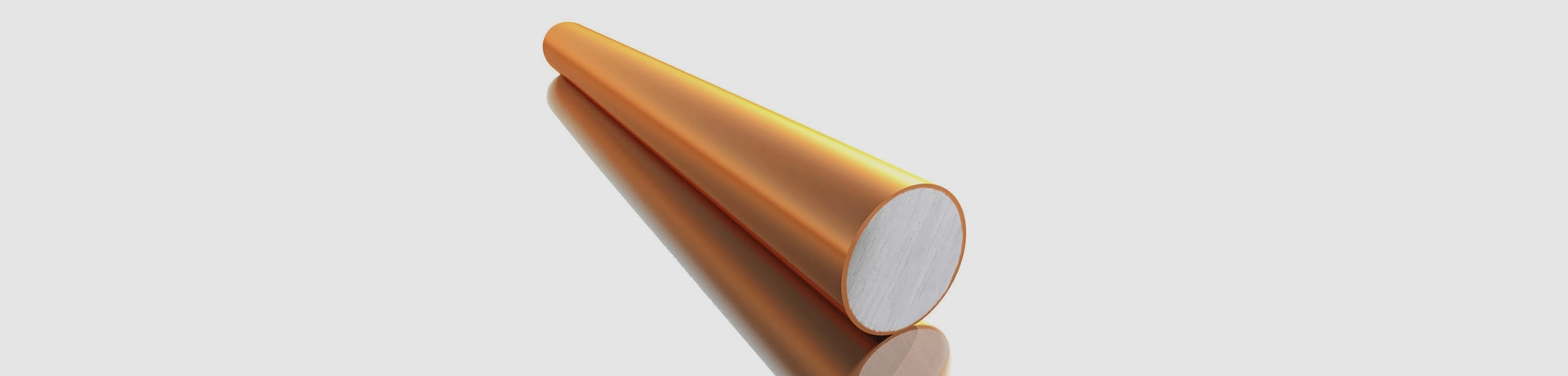

Rongda enameled copper clad aluminum wire (ECCA wire) combines the excellent electrical conductivity of copper with the lightweight properties of aluminum. Thanks to its reliable insulation layer, Rongda ECCA wire shows strong electrical insulation performance, making it suitable for a variety of industries and electrical applications.

Common Applications of ECCA Wire:

Motors, Transformers, and Electromagnetic Coils: ECCA wire is widely used in motor windings and transformer components where both conductivity and weight reduction are critical.

Speaker Coils: The lightweight nature of ECCA wire makes it ideal for speaker coil applications, improving sound response and efficiency.

Household Appliances: Many household devices use ECCA wire due to its balance between performance and cost-effectiveness.

Additional Uses of Enameled Copper-Clad Aluminum Annealing Wire:

Enameled Copper-clad aluminum annealing wire also plays an important role in specialized applications:

Electrical Engineering and Electronic Products: ECCA wire is also suitable for transformers, motor windings, inductors, and other electromagnetic components requiring reliable performance.

High-Frequency Transmission Lines: The favorable skin effect behavior of the ECCA wire makes it efficient for high-frequency signal transmission.

Cables and Wires: ECCA wire is often used in various low-voltage and signal cables, helping to reduce weight and production costs without compromising conductivity.