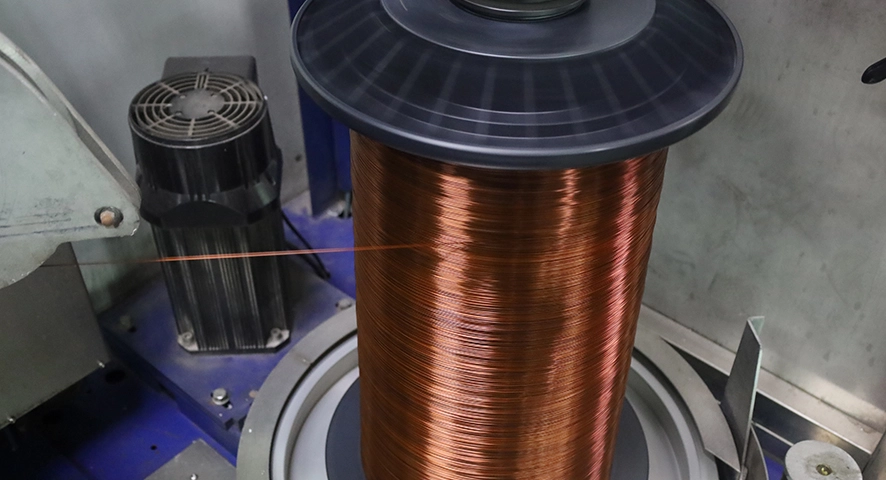

Polyester imide enameled copper wire is an electromagnetic wire widely used in electrical equipment such as motors and transformers. It has the characteristics of high temperature resistance, electrical insulation performance, chemical stability, and good mechanical strength. Due to its excellent performance, it has a wide range of applications in the electrical and electronic industries, especially in situations with high temperature requirements, such as automotive electronics, industrial motors, transformers, and high-speed motors.

| Type | Polyester | Modified Polyester | Polyurethane | Polyesterimide | Polyamide-imide | Polyamide |

| Code | PEW, QZ | PEW, QZ | UEW, QA | EIW, QZY | EI/AIW, QZY/XY | AIW, QXY |

| Thermal Class | Class B, 130°C | Class F, 155°C | Class F, 155°C | Class H, 180°C | Class H, 200°C | Class L, 220°C |

| Insulation thickness | Grade 1, 2, 3 | |||||

| Standard | IEC 60317, NEMA MW, JIS | |||||

| Characteristics | Good heat resistance and mechanical strength. LOW cost. | High mechanical strength, good elasticity, scratch resistance, adhesion, electrical properties and solvent resistance | Solderability (no need to remove the insulation). High frequency resistance and dyeability | Good thermal shock resistance and refrigerant resistance. Excellent chemical resistance, abrasion resistance | More comprehensive performance, with high heat resistance, mechanical properties, refrigerant resistance and chemical resistance | Highest heat class High heat resistance, good solvent and refrigerant resistance |

Polyesterimide copper enamelled wire is a high-performance electromagnetic wire featuring the following distinctive characteristics:

1. Exceptional High-Temperature Resistance: This wire type is typically capable of withstanding temperatures ranging from 155°C to 180°C, with certain specialty variants able to tolerate even higher temperatures.

2. Superior Electrical Insulation Properties

3. Outstanding Chemical Stability: The enameled copper wire exhibits remarkable chemical stability, effectively resisting degradation from exposure to a wide range of chemicals, including acids, alkalis, solvents, and various oils, thereby maintaining its integrity in challenging chemical environments.

4. High Mechanical Strength and Wear Resistance